Leak sealing service

under full operation pressure and temperature

Our on line leaksealing service enables you to keep your production on line while the remedy of the defect is in operation. This prevents you from cost-intensive shut downs and keeps your costs of maintenance down. The operation condition are including nearly all mediums:

- From vacuum up to 240 bar (vacuum to 2.500 psi)

- From 150°C bis + 700°C (-240°F to 1.300°F)

The frequently operated leak sealings are on flanges, valves and pipes.

Bolting service

p

Controlled loading of bolt connections by using hydraulic driven torque equipment.

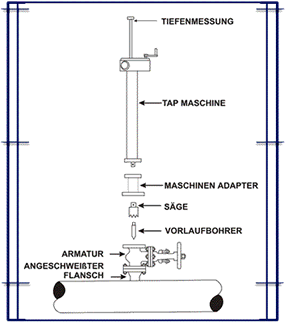

Hottapping und Line Stop

Hottapping means spot boring of pipes / lines / vessels or tanks under pressure. The Hottaping service is possible for a various range of liquid or gaseous products with a maximum pressure rate of 100 bar (1.450 psi) and a maximum temperature of 370°C (700°F).

This method enables you to contain branch connections into pipe nets and change of defect valves without service interruption in a fast and safely matter.

- Measuring rod

- Tapping machine

- Valve Adapter

- Cutter

- Pilot

- AValve

- Fitting

Testing and plugging of Exchanger Tubes

Single tube testing with compressed air or water up to a pressure rate of 180 bar (2.600 psi)

On Site Machining

Pipe freezing

While deep-freezing liquids a shot plug is build which will take on the form of a diabolo caused by the shrinkage of the pipe. This plug is able to resist twice the pipe pressure. Standardwise is the length of the plug threetimes the diameter of the pipe. Precondition is that there is no flow inside the pipe system which has to be frozen.

Scope of application

Rohrwerk has done pipe freezing on pipes from DN 10 up to DN1000 (1/2″ up to 40″). Apart from Water and Oil we have frozen several liquids and products at following production sites and units:

Refineries

Petrochemical plants

Conventional power plants

Public utility companies

Waste inceneration plants

Paper mills and sugar refineries

Coating Systems

Repair material available as paste and repair bandage. Used for repair operations of pumps, valves, pipes, coolers and heat exchangers. Resistant against oily products, hydrocarbons, water, saltwater, dilutions of acid and solvents. Operable temperature range: – 40°C to +140°C ( -40° to 284° F).